Product Introduction

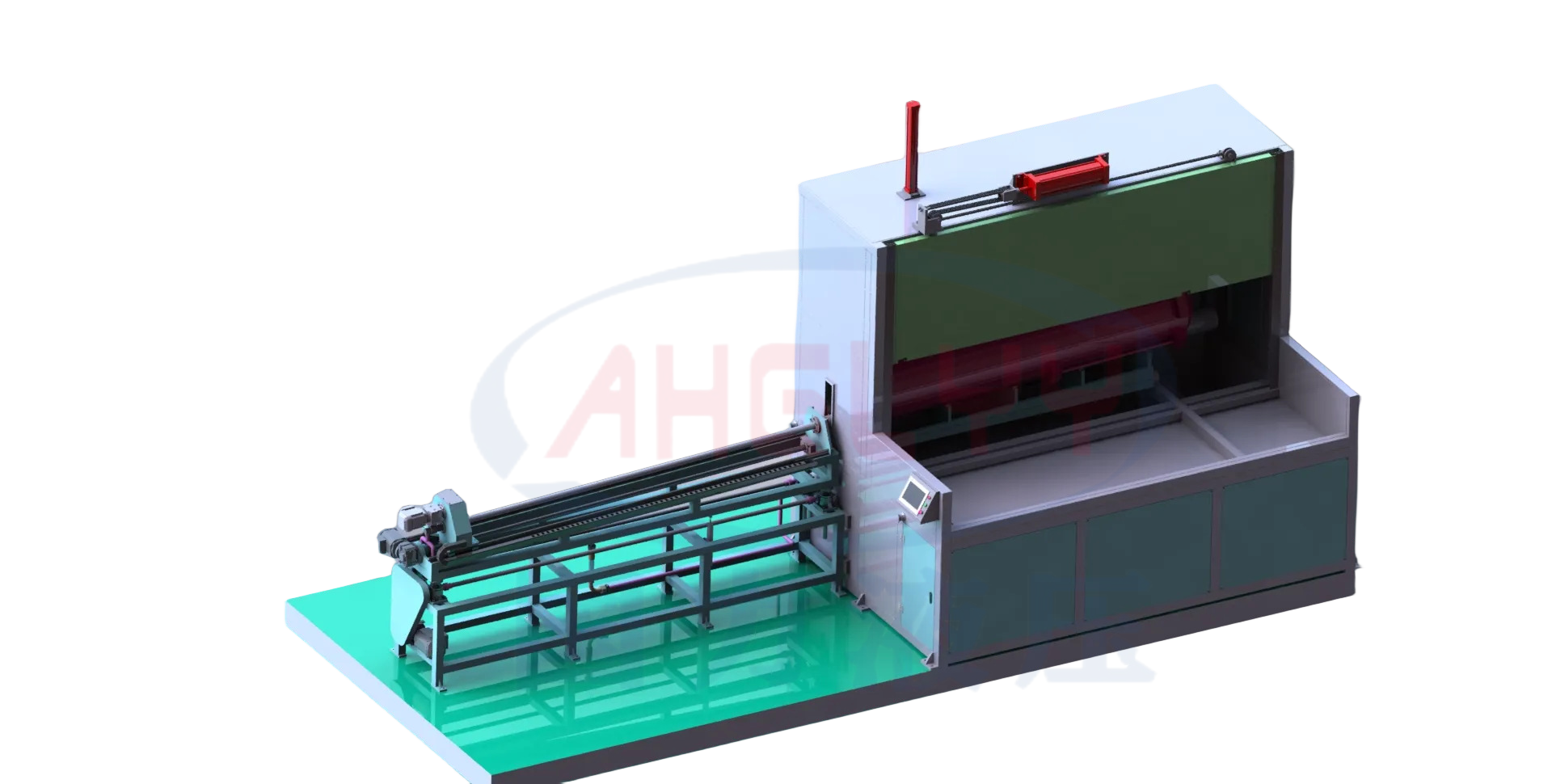

This equipment is mainly used for the flushing and cleaning of complete coal mine hydraulic supports and their main components. After hydraulic supports are lifted out of the mine, a large amount of coal dust and solidified substances remain in their cylinder sockets, connecting rod parts, and base platforms, which are difficult to clean and remove, bringing great inconvenience to disassembly and maintenance. This is a specialized equipment designed to solve the above problems. It uses high-pressure water jet to flush the bonded substances on all parts of the hydraulic support, washes away the solidified substances with water flow, and realizes the cyclic utilization of the cleaning fluid.

In a closed space, the components are transported to the cleaning room by a transport trolley, and the cleaning room door is closed. Operators use a power-assisted manipulator to operate the cleaning gun. The cleaning gun is designed with dual nozzles (high-pressure and large-flow). By operating the power-assisted manipulator manually, the cleaning gun can be aligned to any position on the upper part of the components freely. The handle is equipped with a waterproof switch, which can switch the start and stop of the water pump. The entire cleaning process is completed in a closed space, without the impact of liquid splashing on the environment. Operators work in an operation room that can move freely along the X-Y axis, ensuring safety against high-pressure liquid splashing.

The solid substances conveyed by the scraper conveyor and screw conveyor are compressed by a solid dehydrator, resulting in a water content of less than 20%, which makes them easy to load and transport. The main features of this equipment are energy conservation, environmental protection, safety, reliability, and easy operation.

Technical Parameters

| Item | Parameter |

|---|---|

| Large-flow cleaning pump | Flow rate: 200L/min; Head: 80m |

| High-pressure cleaning pump | Flow rate: 30L/min; Pressure: 50Mpa |

| Transport trolley capacity | 50T |

| Scraper conveyor speed | 2m/min |

| Power pump station pressure | 0-25Mpa |

| Power pump station flow rate | 100L/min |

| Operation room moving speed | 3m/min |

| Compression force of solid-liquid dehydrator | 500KN |

| Total motor power | Less than 90KW/h |

| Solid-liquid separation method | Chemical flocculation + sedimentation |

| Water supply pipe parameter | 0.2Mpa/DN25 |

| Average cleaning efficiency | Per support / 2h |

| Number of operators | 2 persons |

| Power supply capacity | AC380V/110KW |