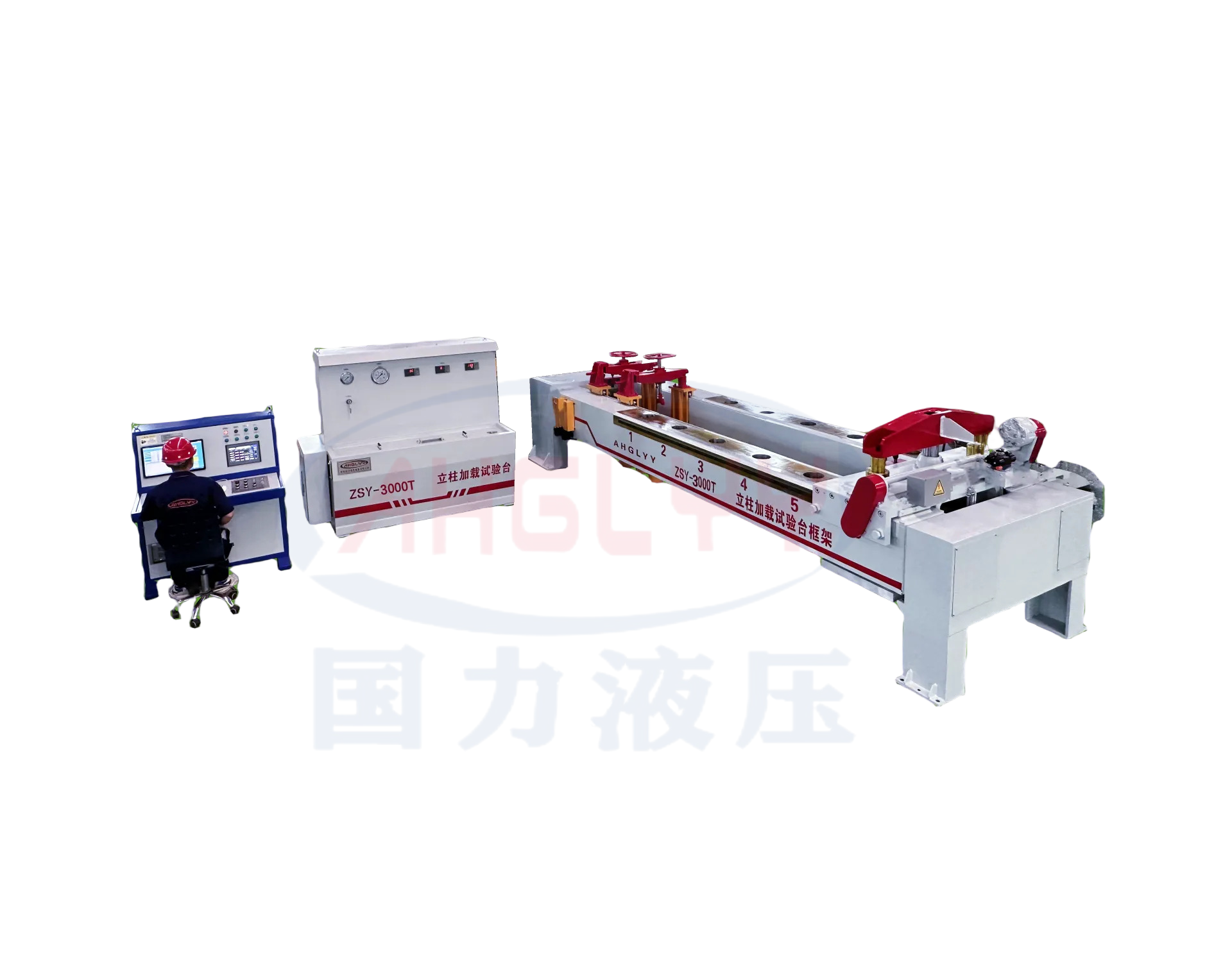

Product Introduction

Developed in accordance with GB/T 25974 - 2010 Hydraulic Supports for Coal Mines (Part 2: Technical Specifications for Columns and Jacks; Part 3: Control Systems and Valves), a national standard, this test bench is mainly used for the factory tests and loading tests of columns and jacks of hydraulic supports. It can also conduct factory performance tests on various valves for hydraulic supports, such as safety valves, pilot - operated check valves, stop valves, directional valves, and high - pressure hoses.

The test bench meets the inspection requirements of the latest national standards. It adopts sensors for data collection and digital instruments for display, and supports two operation modes: computer operation and electrical button operation. The display accuracy reaches 0.01 MPa. It has many characteristics, including safety and reliability, high testing accuracy, and ease of use.

Technical Parameters

Test Pressure: 0 - 80 MPa

Pressure Boost Ratio: 1:4

Motor Power: 37 KW + 6 KW

Test Medium: 5% emulsion

Oil Pump Pressure: 0 - 32 MPa

Built - in Emulsion Pump Pressure: 0 - 6 MPa

Maximum Test Cylinder Bore: 550 mm

Loading Cylinder Inner Diameter: 1000 mm

Built - in Emulsion Pump Flow Rate: 40 L/min

Loading Cylinder Stroke: 600 mm

External Pump Flow Rate: 80 - 400 L/min

Durability Test Cycles: > 100,000 cycles

Column Loading Method: External Loading

Maximum Test Length: 8800 mm

Maximum Loading Force: 30,000 KN

Adjustment Method: Motor - Driven Automatic Adjustment